PROJECT & PROCESS DEVELOPMENT

ABN 26 889 201 980

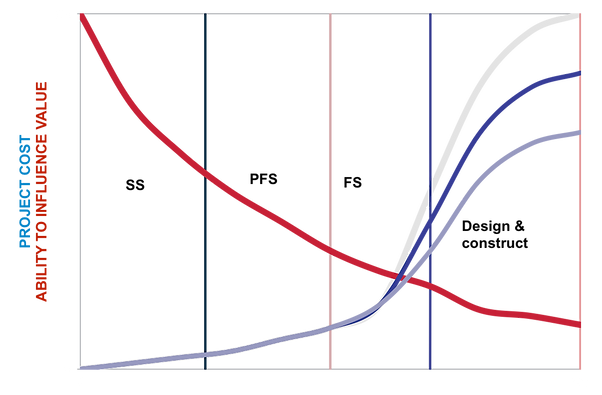

PROJECT DEVELOPMENT PHASES

Scoping Study

-

Aim to find an economic basis for the project to justify further work

-

Decide if a conventional process can be used

-

Start process testwork on costly steps such as comminution, leaching and recovery process for product

-

Determine Mineralogy and Chemical composition

-

Estimate capital and operating costs to Order of magnitude level

-

Early phase marketing study

-

For a well known process and mineral can do scoping study with little test work

Prefeasibility Study

-

Aim of PFS is to select the project option to develop

-

Evaluate all options economically including alternate processes, products, sites, size of project

-

Detailed risk analysis

-

Detailed market study

-

Identify financing and off take partners

-

Determine capital and operating costs for viable options to +/_ 20%-25% accuracy

-

Detailed financial model

-

Range of studies such as environmental, site selection etc

Detailed Feasibility Study

-

Aim of DFS is to develop selected option to obtain project finance

-

Completely define process

-

Improve capital and operating cost accuracy to +/- 10%-15%

-

Detailed risk analysis

-

Complete 10% of engineering

-

Obtain environmental and other approvals

FEED

-

Front End Engineering and design - a loose term covering engineering from DFS stage to start of construction

Detailed Engineering

-

Complete process engineering deliverables

-

Detailing of the DFS defined process to obtain a control estimate +/- 5% -10%

-

Complete 40% of engineering

-

Sufficient detail to purchase major and long lead equipment

Construction

Commissioning

Operation

As the project progresses the ability to change the final project value decreases and cost of making changes increases. Not selecting the optimum project option in PFS can dramatically reduce overall project value.

TEST WORK STAGES

Preliminary

Desk top tests to prove process flowsheet

Basic Design Information

Closed Circuit Tests

Locked cycle

Variability tests

Piloting

Demonstration Plant

PRELIMINARY /SCOPING TEST WORK

Mineralogy

Chemical composition

Evaluate if a conventional process can be used

Sighter tests for key processes such as comminution and leaching

Establish simple test to use to evaluate ore amenability to process

Can evaulate known ores and process with little test work

PRE-FEASIBILITY STUDY TEST WORK

Aim of the PFS testwork is to confirm the process selected

Bulk of testing is during the PFS

Evaluate different processes & products

Process steps tested firstly separately at bench scale

Combined process steps then tested with recycles streams

Recycles in equipment that cannot easily be run continuously on small scale be may be done in locked cycles

Vendor test work to obtain physical data such as settling, filtration etc

Piloting may be required for novel processes, new equipment

Larger scale demontration plant my be needed to produce bulk samples, test physical behaviour of material in equipment ( solid flow in high temperature equipment)

Conventional processes testwork can be done quickly and time and cost be reliably estimated

New processes require tests in sequence and this means for an extended period. Costs are dependant on whether alternate process steps need to be tested.

PILOTING

Prove that all process steps can operate together continuously

Test at a scale to get engineering data and measure process efficiency

Can identify problems in the integrated process

Provides opportunity to test a range of construction materials

Provides product for testing and marketing

FEASIBILITY STUDY TESTWORK

Confirm viability of selected process

Provide detailed design data and info required by vendors

Continuous piloting if required to provide confidence in process

Variability on expected feed from mine plan

DEMONSTRATION PLANTS

Primarily for risk reduction

May need bulk samples of product to obtain oftake agreements

Prove new equipment

Are extremely costly

Long time to build and operate

Need deep pockets and resolve to commercialise a new process

Piloting a process at ANSTO for Arafura Resources

Palmag Evaporative crystalliser Demonstration plant at Foskor site